Isingeniso senqubo yokukhiqiza

Le nqubo yokukhiqiza isebenzisa ikheji lokuxilonga elinemishini ukuze kudliwe.Ayinazo izidingo zezinto zokusetshenziswa ze-sludge (akukho ukungcola≥5CM).Kulula futhi kulula, konga umsebenzi nesikhathi, kunciphisa izindleko futhi kuthuthukisa ukusebenza kahle.

1. Ukondla: (isisele esivaleke ngokuphelele sisethiwe)

Ngemuva kokuthi izinto zifakwe esiseleni ngekheshi, qala ivalve yokuphakela kanye ne-auger yokudla, futhi ngokulinganayo ufake i-auger noma i-hydraulic feeder ngokwezinga elimisiwe, bese usebenzisa okokuphakelayo ukondla izinto ezisetshenziswayo eketelani eliqhekekayo.

2. I-Pyrolysis

Ukuqhekeka, setha izinga lokushisa elingu-350℃- 470℃.Ijubane lokujikeleza kweketela eliqhekeka yimizuzwana eyi-150 indilinga ngayinye.Ngemuva kokuqedwa kokuqhekeka kwe-sludge yamafutha, insalela ingena ku-extractor ye-slag, ethumela izinsalela emgqonyeni we-slag opholile ngamanzi.Izinsalela zifakwa ngokuzenzekelayo esikhwameni sethani ukusuka ekushiseni okuphezulu kuye ezingeni lokushisa elivamile futhi zipakishwe ukuze zigcinwe okwesikhashana.

3. Ukushisa, ukulawula ingcindezi

I-fuel gas evumelana nemvelo isetshenziselwa ukufudumeza.Ukuqhekeka kwezinga lokushisa eliphezulu kufakwe izinjini ezine zikaphethiloli ezingama-30w kanye nezibhamu ezine zokufuthwa kwegesi, zonke zilawulwa ngobuhlakani ukuze kuqinisekiswe izinga lokushisa elijwayelekile elidingekayo ekukhiqizweni kokuqhekeka.

Ingcindezi yokuklama ukukhiqizwa kwemishini ijwayelekile, ingcindezi evamile yokukhiqiza ingu-0.01MPa - -0.02MPa, kanti ukucindezela okukhulu kwesethi yi-0.03MPa.Phakathi nenqubo yokukhiqiza, inzwa yokulawula ingcindezi inikeza isignali yokuzwa ingcindezi.Uhlelo lokulawula ukucindezela luvula noma luvale i-valve yokulawula ukucindezela ngokuhambisana nengcindezi ebekiwe, bese ithumela isikhumbuzi se-alamu ukuze kuqinisekiswe ukukhiqizwa okuphephile kwemishini.

3.4 Inqubo yokukhiqiza

Ngaphambi kokukhiqiza, hlola ukuthi idivayisi kagesi yokushayela ijwayelekile yini, okuhlanganisa (isifunda, isinciphisi, isiphephetha-moya, isiphephetha-moya esingeniswayo, iphampu yamanzi ejikelezayo), ukuthi iwintshi yokuphakelayo kanye newintshi yokukhipha amandla isebenza ngokujwayelekile, nokuthi ikhabhinethi yokusabalalisa amandla ehlakaniphile inalo yini iphutha. (thintana nabasebenzi bezokulungisa ngaphambi kokwehluleka, futhi ungayiqali ngokuqondile)

Isiteji sokudla

Isiteji sokukhiqiza: ngaphambi kokukhiqiza, hlola ukuthi injini kaphethiloli, iphampu yomoya, i-compressor yomoya kanye ne-blower zijwayelekile yini, hlola ukuthi uphawu lwamanzi lushoda yini ngamanzi, gcina i-valve yokuphuma komoya yewintshi ivulekile, gcina ivalve yokuphuma ye-slag ivaliwe, futhi gcina i-valve yokukhipha umoya yesigubhu sesitimu ivuliwe, bese wenza isithando somlilo sijikelezise siye phambili cishe imizuzwana eyi-100/umyingi ngokusebenzisa ukusebenza kwekhabhinethi yokusabalalisa amandla ohlakaniphile.Lapho injini yamafutha ivulwa ukuze inyuse izinga lokushisa ngo-50℃, vala i-valve ye-vent yesisabalalisi segesi, Khulisa kancane izinga lokushisa libe ngu-150℃- 240℃, futhi igesi engacondensable iqala ukukhiqizwa.Ithunyelwa esithandweni somlilo ukuze kushiswe ngesistimu yokubuyisela igesi yamafutha.Ngokwenani legesi engacondensable, cisha inani lezinjini zikaphethiloli ukuze ulondoloze isimo somlilo ongasheshi.(Uma inani legesi engacondensable likhulu, lizothunyelwa kwelinye iqoqo lezinto zokusebenza ukuze lishiswe ngamavalvu aphathwayo. Uma ezinye izinto ezisetshenziswayo zingayidingi, igesi engacondensable eyeqile ingathunyelwa egumbini lesibili lokuvutha), futhi bese ukhuphuka kancane ufike ku-380-450℃.Qinisekisa ukuthi ukuqhekeka kuhlanzekile.Ukuncipha kwegesi engacondensable,

Isistimu yokuhlanza i-nitrogen;Isetshenziswa kakhulu ukuhlanza igedlela lokuhlanza, umamukeli wegesi, i-condenser, isihlukanisi segesi kawoyela kanye nomgqomo we-slag opholiswe ngamanzi ukuze esikhundleni segesi engajiki nge-nitrogen.Qinisekisa ukuphepha kokukhiqizwa kwemishini.

Isistimu ye-slagging;Ngaphambi kokukhishwa kwe-slag, i-valve ye-air outlet ye-winch cage izovalwa ngekhabhinethi kagesi ehlakaniphile, uhlelo lokupholisa umlotha luzovulwa ukuze ludluliselwe, futhi ipompo yamanzi ejikelezayo izovulwa.Lapho i-valve yamafutha esindayo ivulwa, inani elincane lamafutha asindayo kufanele likhishwe kuqala ukuze kugwenywe ukunamathela ekhejini lokukhipha i-slag.Vala i-valve kawoyela esindayo ngemva kokukhishwa kwamafutha anzima.Umzimba wesithando somlilo uyahlehla futhi uqala ukukhishwa kwe-slag amahora angu-1-1.5.

Izinto zeketela lokuqhekeka: 316L insimbi engagqwali Q245RQ345R kazwelonke standard boiler steel plate

Usayizi weketela le-pyrolysis:φ 2800MM*7700MM

Ivolumu nokushisa kwendawo yegedlela eliqhekekayo: 47m3 kanye no-80m2

Imodi ye-Condensation nendawo yokushintshanisa ukushisa: ukupholisa amanzi 90m2

Ifomu lesakhiwo esiyinhloko: ukuzungezisa okuvundlile

Ukucindezela kwesistimu: ingcindezi evamile

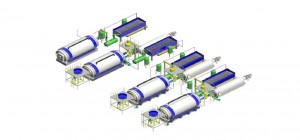

Indawo yezisetshenziswa: 50m ubude, 10m ububanzi kanye 6m ukuphakama

Isisindo semishini: 50-60t

Inqubo yobufakazi bokuqhuma: zonke izinto zikagesi zifakelwe izinto zikagesi ezijwayelekile ze-YB ezingaqhumi

Ukusetshenziswa kukaphethiloli: I-600 m yegesi yemvelo isetshenziswa ngosuku ngohlobo oluqhubekayo³/ D idinga u-500L/D wamafutha kaphethiloli

Uhlelo lwamandla nokusabalalisa: imishini ifakwe amandla aphelele angama-46.4 kilowatts.

Ikhabhinethi eyodwa yokulawula ideskithophu ehlakaniphile ifakwe (ukulawula amandla, izinga lokushisa, i-alamu yokubonisa ingcindezi yedijithali, ukusebenza kwevalvu ehlakaniphile kwesikrini sokuthinta neminye imisebenzi).

Isilinganiso sokusatshalaliswa kwamandla ngehora ngama-30kw, futhi ukusatshalaliswa kwamandla kwansuku zonke cishe amahora angama-500-600 kilowatt..

Isikhathi sokuthumela: Jan-09-2023