Igromegranate Concentrate Juice Production Line

- Isimo:

- Okusha

- Indawo Yomsuka:

- Shanghai, China

- I gama le-brand:

- I-OEM

- Inombolo Yemodeli:

- I-JPF-GZ3857

- Uhlobo:

- iphrojekthi yokhiye wokuvula

- Amandla kagesi:

- 220V/380V

- Amandla:

- 2.2kw

- Isisindo:

- 200kg

- Ubukhulu(L*W*H):

- 1380*1200*2000mm

- Isitifiketi:

- CE ISO

- Isiqinisekiso:

- Iminyaka emi-2, iminyaka emi-2

- Isevisi yangemuva kokuthengisa Ihlinzekiwe:

- Onjiniyela abatholakalayo ukusevisa imishini phesheya kwezilwandle

- Igama lomkhiqizo:

- ihalananda concentrateumugqa wokukhiqiza ijusi

- Umbala:

- Izidingo Zamakhasimende

- Okubalulekile:

- Insimbi Engagqwali 304

- Isicelo:

- Impande Imifino

- Umsebenzi:

- Imisebenzi eminingi

- Amandla:

- 2-10t/h

- Ukusetshenziswa:

- Ukusetshenziswa Kwezimboni

- Into:

- Iphrojekthi ye-Turnkey

- Isici:

- Ukusebenza Okuphezulu

- Ikhono Lokuhlinzeka:

- 10 Isethi/Amasethi Inyanga ngayinye

- Imininingwane yokupakisha

- iphakethe ebhokisini

- Itheku

- Shanghai

- Isikhathi esiholayo:

- ezinyangeni ezi-3 noma ngaphansi

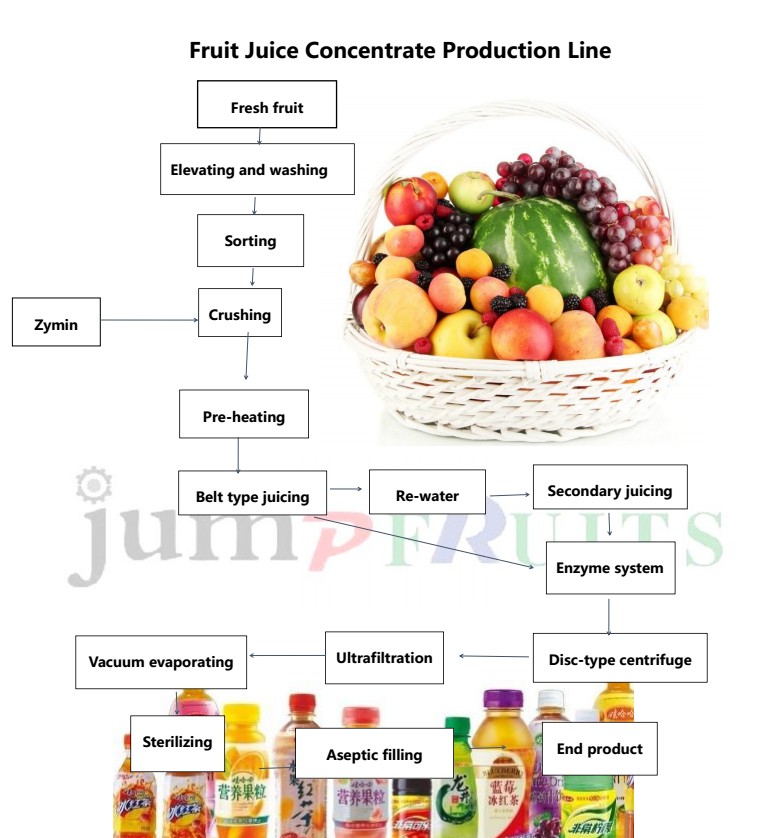

Umugqa wokukhiqiza ijusi yezithelo

Izinzuzo Zethu:

1.Isixazululo se-Turnkey.Asikho isidingo sokukhathazeka uma wazi okuncane mayelana nendlela yokwenza lesi sitshalo ezweni lakini. Asikunikezeli nje kuphela okokusebenza, kodwa futhi sihlinzeka ngezinsizakalo zokuma okukodwa,kusukela ekuklanyweni kwendawo yakho yokugcina impahla (amanzi, ugesi, abasebenzi), ukuqeqeshwa kwezisebenzi, ukufakwa komshini nokulungisa iphutha, insizakalo yempilo yonke ngemva kokuthengisa njll.

Iminyaka engu-2.15 isipiliyoni sokuthekelisa, ukuthutha kalula impahla uye emnyango wakho

I-3.isevisi eyenziwe ngokwezifiso, sizozama konke okusemandleni ethu ukuze sihlangabezane nemfuneko yakho.

4.Isiqinisekiso sekhwalithi: izinyanga eziyi-12.Ngemva kwalokho, onjiniyela nabo bayatholakala ezindlekweni zakho zokuhamba kanye nezindleko zezingxenye ezisele.Sinikeza isevisi yempilo yonke ngemva kokuthengisa.

Izinzuzo eziyinhloko zomugqa wethu wesistimu:

1. Ijubane eliphezulu lokukhiqiza elizuzwe ngesistimu yekhanda esanda kuklanywa (ikhanda elilodwa noma amakhanda angamawele atholakalayo), ukwethembeka okuthuthukisiwe kusuka kumodi yokusebenza elawulwa ngokugcwele ye-PLC yokuxilonga.

2. Ukuguquguquka okukhulu ngokuhlangabezana namazinga ahlukahlukene okupakisha ngemikhiqizo ehlukene.

3 Isebenzisana kahle neshubhu yesibulali magciwane seshubhu, uma ukungasebenzi okuthile ngesigcwalisi, umkhiqizo uzogeleza ubuyele ethangini le-buffer ngaphambi kwesibulala-magciwane se-UHT.

4. Ukusetshenziswa kwesikhwama esingenalutho esivalwe nge-hermetically kuqinisekisa ukuthi isikhwama sizohlala siyinyumba ngaphambi kokuba sigcwaliswe.

5. I-high pressure saturated steam isetshenziselwa ukuvalwa inzalo kokufakwa, i-cap kanye nengxenye eveziwe yesigcwalisi ngaphambi komjikelezo ngamunye wokugcwalisa.AKUKHO KHEMIKALI kudingekile.

6. Ukubekwa uphawu kwe-valve yokugcwalisa ngaphakathi kwendawo yokufakwa kugcina umkhiqizo ungekho ngokuphelele endaweni yokuvala iphakheji.

7. Ukuvalwa kokushisa kwe-hermetic kokufakwa kunikeza ukuvala okubonakalayo kwe-tamper kanye nomgoqo we-oxygen ophakeme.

8. Umklamo jikelele we-aseptic we-filler uvumela ukungaphazanyiswa.Ukusebenza kuyo yonke inkathi katamatisi/yezithelo, ukhulise ukusebenza kahle kwesitshalo sakho

9. I-CIP kanye ne-SIP kuyatholakala kanye neshubhu yesibulali magciwane

Siyakwamukela noma yimuphi umbuzo!Tel/Wechat/Whatsapp:008613681836263

Automatic juice izithelo processing plant

1.Wonke ulayini uyazenzakalela

2.Setha ukuwasha, ukugcwalisa kanye nokufaka imisebenzi emithathu emzimbeni owodwa

3.ifanele ukushisa okuphezulu ukumelana nejusi yebhodlela le-PET kanye nokugcwalisa isiphuzo setiye

4.yenziwe ngekhwalithi ephezulu ye-SUS304stainless steel

5.ukusebenzisa isikrini sokuthinta ukuze sisebenze

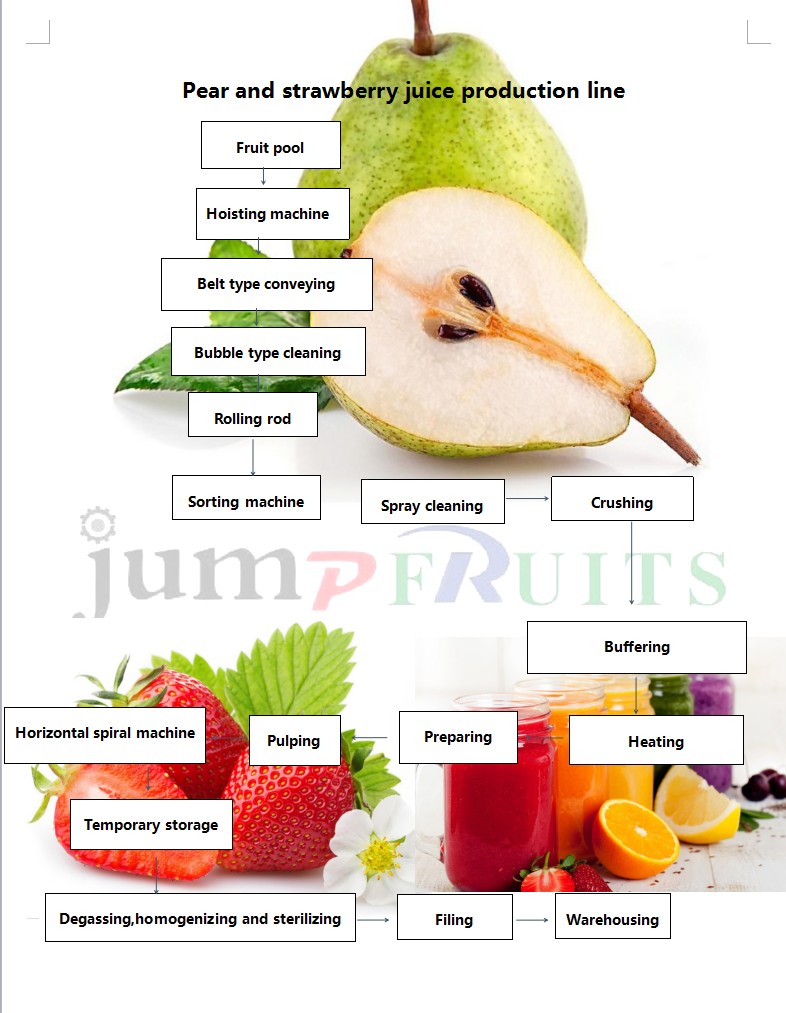

Ulayini wokukhiqiza ijusi yezithelo uhlanganisa umxube wempuphu wamanzi, isihlungi sesiraphu, isihlungi se-duplex, i-vacuum degasser, i-UHT sterilizer ne-homogenizer, njalonjalo.Impahla eluhlaza ingaba isithelo esisha noma ijusi egxilile.Ingasetshenziselwa ukwenza ulayini wokukhiqiza ijusi yewolintshi, ulayini wokukhiqiza ijusi ye-apula, ulayini wokukhiqiza ijusi yepentshisi, kanye nolayini wokukhiqiza ijusi yecherry njll. Singakwazi futhi ukuklama imigqa yokukhiqiza ngokwezifiso ngokuhambisana nezidingo zamakhasimende.

Inqubo yokukhiqiza:

I: ukukhetha kwezinto zokusetshenziswa

Khetha ukunambitheka okuvuthwe ngokugcwele, okusha, okuhle nokucebile ngojusi, azikho izifo zezitshalo nezinambuzane ze-TaoGuo, ukuvuthwa okwanele kwe-TaoGuo kufanele kudlule ngemva kokupheka.

II: ukunakekelwa kwempahla eluhlaza

1.clean.Izinto ezingavuthiwe zikhethwa ngemva kokuhlanza ngamanzi ahlanzekile okugeza kanye ne-brush ku-MAO net ku-1% isixazululo se-hydrochloric acid noma isixazululo se-detergent futhi ngemva kokuhlanza, susa izinsalela zezibulala-zinambuzane, bese uhlanza emanzini ahlanzekile, ukhiphe kahle.

2.sika uhhafu ukuze ungene ku-nuclear.Gemba umshini wenuzi usike phakathi.

3.cwilisa vikela umbala.Sika ngemva kokumba izinto zenuzi ngo-0.1%.Ingxube ye-ascorbic acid ne-citric acid solution cwilisa ivikela umbala.

III:ukushaya ukushisa

Isiqephu sesithelo esingaphansi kuka-90 ° C kuya ku-95 ° C, ukushisa imizuzu emi-3 kuya kwemi-5, ukuthambisa, ukushaya ngosayizi wembotshana we-0.5 mm beater, susa isikhumba.

IV: ukulungiswa kwe-flavour

Ngemva kokubhekana noqweqwe lwe-pulp yesithelo ukuze kwandiswe ukunambitheka okufanele kulungiswe.Lungisa engeza ushukela, i-citric acid ne-L - i-ascorbic acid nezinye izithako.Isilinganiso saso se-peach pulp 100 kg, 80 kg 27% isixazululo sikashukela, i-citric acid. , L - ascorbic acid 0.07 0.45 kg - 0.2 kg.

V: i-homogeneous degassing

Homogeneous iwukuba ukwenza juice uginindela izinhlayiya imisiwe uqhekeke zibe izinhlayiya ezincane futhi nombala zihlakazekile kule juice isithelo, ukwandisa ukuzinza juice yezithelo, ukuvimbela stratification.

1.Indlela elinganayo iwukuba uhlanganise ijusi yokuhlunga nge-homogenizer yomfutho ophezulu, wenze ijusi ezinhlayiyeni ze-pulp kanye nempahla ye-colloid ngengcindezi ephezulu ngokusebenzisa u-0.002 0.003 mm ububanzi bezimbobo futhi ibe izinhlayiya ezinhle kakhulu.Ivame ukusetshenziswa ekukhiqizeni kuka-130-160 kg. /cm2 homogenizer.Ingase futhi isetshenziselwe isigayo homogeneous colloid.Lapho ijusi ngokusebenzisa igebe colloid lesigayo of 0.05 0.075 mm ukuqhekeka, in izithelo uginindela granules by eqinile centrifugal force kanye ukungqubuzana mutual umthelela, ngaleyo ndlela kuzuzwe homogeneous.Lapho ijusi yezithelo ku-oksijini, i-nitrogen ne-carbon dioxide namanye amagesi, phakathi kwawo, i-nitrogen ingabangela uvithamini C kanye nezinto ze-pigment ezifana ne-oxidation nokugqwala kwamathini e-tinplate, ngakho-ke, kufanele kube yi-degassing, indlela ye-degassing ngokuyisisekelo inezinhlobo ezimbili ezilandelayo: indlela yokukhipha i-vacuum.Ijusi esitsheni se-vacuum yenza ijusi kujethi yenkungu encane kanye ne-degassing.Kuthathwe indlela ye-vacuum ye-vacuum degree ingu-685-711 mm hg noma ngaphezulu, izinga lokushisa lingaphansi kuka-43 °C.

2.indlela yokushintshanisa i-nitrogen.Ijusi elisuka eshubhuni lengilazi elime mpo noma ishubhu lensimbi engagqwali phezulu libe umfutho wenitrogen osuka phansi.I-nitrogen ngemva kokuhlanganisa amabhamuza amancane akheke kujusi yesithelo, yashintsha umoya-mpilo ejusi yesithelo futhi yafinyelela umgomo. wokukhipha umoya.

VI: ithangi lokuvala inzalo

Ijusi ishisiswe ibe ngu-95 °C.Kuthatha iminithi elingu-1, isimangalo singakwazi ngokushesha.

VII: ukupholisa okuvaliwe

Khipha isivalo sebhodlela, ithangi liphenduke umzuzu owodwa. Ngokushesha ngemva kokuba uphawu luhlukanise ukupholisa ngezigaba lube ku-38 °C noma ngaphezulu, kwase kuba indawo yokugcina impahla. Imikhiqizo yetiye yezithelo efanelekayo inombala obomvana noma onsundu ngokuphuzi, ivunyelwe ukuba bomvu ngokumnyama; ukufiphala kweyunifomu ye-SAP, ngemuva kwezinhlayiya zokuphumula kwesikhathi eside ziyancibilika;Nokunambitheka kwejusi yepentshisi, ngaphandle kwephunga elingavamile; Okuqinile okuncibilikayo kwakungu-10% - 14%

1.Umthamo:1000-30000bph

2.Usayizi webhodlela: 250-1500ml

3.Yamukela umklamo okhethekile

I-4.CE ISO igunyaziwe

Ukwethulwa komugqa wokukhiqiza ijusi ye-PET / ingilazi ye-orange / umango

1) Umshini usetshenziswa kakhulu ekusebenzeni kokugcwalisa isiphuzo.Imisebenzi emithathu yokugeza amabhodlela, ukugcwalisa kanye nokuvala uphawu yenziwa emzimbeni owodwa womshini.Lonke lolu hlelo luyazenzakalela.Umshini usetshenziselwa ukugcwalisa amajusi, amanzi amaminerali kanye namanzi ahlanzekile emabhodleleni enziwe nge-polyester namapulasitiki.

I-2) Umshini ungasetshenziswa futhi ekugcwaliseni okushisayo uma ufakwa ngedivayisi yokulawula izinga lokushisa.Isibambo somshini singashintshwa ngokukhululekile futhi sizikhandle ukuze silungise umshini ukuze ugcwalise izinhlobo ezahlukene zamabhodlela.

I-3) Ukusebenza kokugcwalisa kuyashesha futhi kuzinzile ngoba ukusebenza kokugcwalisa i-micro pressure yohlobo olusha kwamukelwa.Lapho okukhiphayo kanye nenzuzo yomshini iphakeme kunemishini yokucaciswa okufanayo.Isilawuli esithuthukisiwe se-OMRON (PLC) samukelwa ukulawula umshini ukuthi usebenze ngokuzenzakalelayo ngenkathi i-transducer isetshenziswa emaketangeni afaka ibhodlela ukulungisa isivinini futhi ihlanganiswe ne-transducer yomshini omkhulu ukwenza imisebenzi yokuhambisa ibhodlela phambili kancane kancane futhi ngokwethembekile.

I-4) Kulula ukusebenza nge-automation ephakeme ngoba yonke ingxenye yomshini ihlolwe ukuze isebenze ngogesi wesithombe, Ezisekelweni, izingxenye zokugcwalisa zomshini zingashintshwa zibe izindlela zokugcwalisa i-vacuum ephansi.

5) Isigaba sokugcwalisa se-vacuum ephansi (umshini wohlobo lwe-Z) sisebenza emabhodleleni engilazi, ukugcwalisa utshwala, isoya nokunye okunjalo.Isigqoko sobufakazi bokweba i-aluminium kanye nesigqoko sepulasitiki singamukelwa.Umshini uyisisetshenziswa esikhethwa wumbono sabakhi beziphuzo.

Izici ze-PET / ibhodlela lengilazi umugqa wokukhiqiza ijusi yemango

1. Ukusebenzisa umoya wathumela ukufinyelela futhi ukuhambisa isondo ebhodleleni ngqo exhunywe ubuchwepheshe;isikulufu esikhanseliwe namaketango okuhambisa, lokhu kwenza ukuthi ushintsho olumise okwebhodlela lube lula.

2. Ukuhanjiswa kwamabhodlela kusebenzisa ubuchwepheshe be-clip bottleneck, uguquko olumise okwebhodlela aludingi ukulungisa izinga lemishini, kwanele ukuguqula okuhlobene nepuleti eligobile, izingxenye zesondo nezenayiloni.

3. Isiqeshana somshini wokuwasha ibhodlela lensimbi engagqwali esiklanywe ngokukhethekile siqinile futhi siqinile, akukho ukuthinta ngendawo yesikulufu yomlomo webhodlela ukuze kugwenywe ukungcoliswa kwesibili.

4. I-valve yokugcwalisa i-valve yokugcwalisa i-valve yesivinini esikhulu, igcwalisa ngokushesha, igcwalise ngokunembile futhi akukho uketshezi olulahlekelwayo.

5. Ukwehla kwe-Spiraling lapho ibhodlela eliphumayo, guqula isimo sebhodlela asikho isidingo sokulungisa ukuphakama kwamaketanga okuhambisa.

6. Umsingathi usebenzisa ubuchwepheshe bokulawula okuzenzakalelayo obuthuthukisiwe be-PLC, izingxenye zikagesi ezibalulekile ezivela enkampanini edumile njengeMitsubishi yaseJapan, i-France Schneider, i-OMRON.

Isevisi yangaphambi kokuthengisa

Singaphakamisa ikhasimende umshini ofaneleka kakhulu ngokuya ngefomula yawo kanye nempahla eluhlaza.“Ukuklama nokuthuthukiswa”, “ukukhiqiza”, “ukufakwa nokugunyazwa”, “ukuqeqeshwa kobuchwepheshe” kanye “nesevisi yangemuva kokuthengisa”.Singakwethula umphakeli wezinto ezingavuthiwe, amabhodlela, amalebula njll. Siyakwamukela kuworkshop yethu yokukhiqiza ukuze ufunde ukuthi unjiniyela wethu ukhiqiza kanjani.Singakwazi ukwenza ngokwezifiso imishini ngokwesidingo sakho sangempela, futhi singathumela unjiniyela wethu efektri yakho ukuze afake imishini futhi aqeqeshe isisebenzi sakho sokuSebenza nokulungisa.Ezinye izicelo.Vele usazise.

Isevisi yangemuva kokuthengisa

1.Ukufakwa kanye nokugunyazwa: Sizothumela onjiniyela abanolwazi nabasebenzi bezobuchwepheshe ukuthi babe nesibopho sokufakwa nokusetshenziswa kwezisetshenziswa kuze kube yilapho okokusebenza sekufanelekile ukuze kuqinisekiswe ukuthi okokusebenza kusesikhathini futhi kuyafakwa ekukhiqizeni;

2.Ukuvakasha okuvamile:Ukuqinisekisa ukusebenza okuzinzile kwesikhathi eside kwemishini, sizobe sisekelwe ezidingweni zamakhasimende, sinikeze okukodwa kuya kwezintathu ngonyaka ukuze size ekusekelweni kwezobuchwepheshe nezinye izinsizakalo ezididiyelwe;

3.Umbiko wokuhlola onemininingwane: Kungakhathaliseki ukuthi isevisi evamile yokuhlola, noma isondlo saminyaka yonke, onjiniyela bethu bazohlinzeka ngombiko wokuhlola onemininingwane yekhasimende kanye nenqolobane yereferensi yenkampani, ukuze kufundwe ukusebenza kwesisetshenziswa nganoma yisiphi isikhathi;

I-4.I-inventory yezingxenye ezigcwele ngokugcwele: Ukuze unciphise izindleko zezingxenye ku-inventory yakho, unikeze isevisi engcono futhi esheshayo, silungiselele iqoqo eliphelele lezingxenye zemishini, ukuhlangabezana namakhasimende isikhathi esingenzeka sokufuna noma isidingo;

5.Ukuqeqeshwa kochwepheshe kanye nobuchwepheshe:Ukuze kuqinisekiswe ukusebenza kwezisebenzi zezobuchwepheshe zekhasimende ukujwayela okokusebenza, ukubamba kahle ukusebenza kwemishini nezinqubo zokuyilungisa, ngaphezu kokufaka ukuqeqeshwa kobuchwepheshe esizeni.Ngaphandle kwalokho, ungakwazi futhi ukubamba zonke izinhlobo zochwepheshe kuma-workshops asefekthri, ukukusiza ukubamba ubuchwepheshe obushesha futhi obuphelele;

6.Izinsizakalo zeSoftware kanye nezokubonisana: Ukuze uvumele abasebenzi bakho bezobuchwepheshe ukuba babe nokuqonda okwengeziwe kokwelulekwa okuhlobene nemishini, ngizohlela ukuthumela amathuluzi athunyelwa njalo kumagazini wezeluleko kanye nolwazi lwakamuva. Asikho isidingo sokukhathazeka uma wazi okuncane ngakho. ungasifeza kanjani lesi sitshalo ezweni lakini.Asikunikezeli nje kuphela izinto ezisetshenziswayo, kodwa futhi sihlinzeka ngensizakalo yendawo eyodwa, kusukela ekuklameni kwakho kweshede (amanzi, ugesi, umusi) , ukuqeqeshwa kwesisebenzi, ukufakwa kwemishini nokulungisa iphutha, impilo yonke isevisi yangemuva kokuthengisa njll.