Gcwalisa Umugqa Wokucutshungulwa Kwesithelo Esisha Okuzenzakalelayo / Umugqa Wokukhiqiza Isiphuzo

- Isimo:

- Okusha

- Indawo Yomsuka:

- Shanghai, China

- I gama le-brand:

- I-JUMPRUITS

- Inombolo Yemodeli:

- I-JPF-YL8562

- Uhlobo:

- UMUGQA WOKUQHUBEKA

- Amandla kagesi:

- 220V/380V

- Amandla:

- 3 kw

- Isisindo:

- 60 amathani

- Ubukhulu(L*W*H):

- 1380*1200*2000mm

- Isitifiketi:

- ISO9001,CE

- Isiqinisekiso:

- 1 Unyaka

- Isevisi yangemuva kokuthengisa Ihlinzekiwe:

- Onjiniyela abatholakalayo ukusevisa imishini phesheya kwezilwandle

- Okubalulekile:

- 304 Insimbi Engagqwali

- Igama lomkhiqizo:

- I-Shanghai Fruit Juice processing plant

- Isicelo:

- Impande Imifino

- Into:

- I-Automatic Fruits Juicer Machine

- Igama:

- Umshini Wokusika Imifino

- Umsebenzi:

- Imisebenzi eminingi

- Ukusetshenziswa:

- Izimboni Zokucubungula Ukudla

- Amandla:

- 3-5t/h

- Umbala:

- Izidingo Zamakhasimende

- Isici:

- Ukusebenza Okuphezulu

- Ikhono Lokuhlinzeka:

- 3 Isethi/Isethi Inyanga ngayinye

- Imininingwane yokupakisha

- ibhokisi lebhokisi

- Itheku

- i-Shanghai

- Isikhathi esiholayo:

- izinsuku ezingu-60

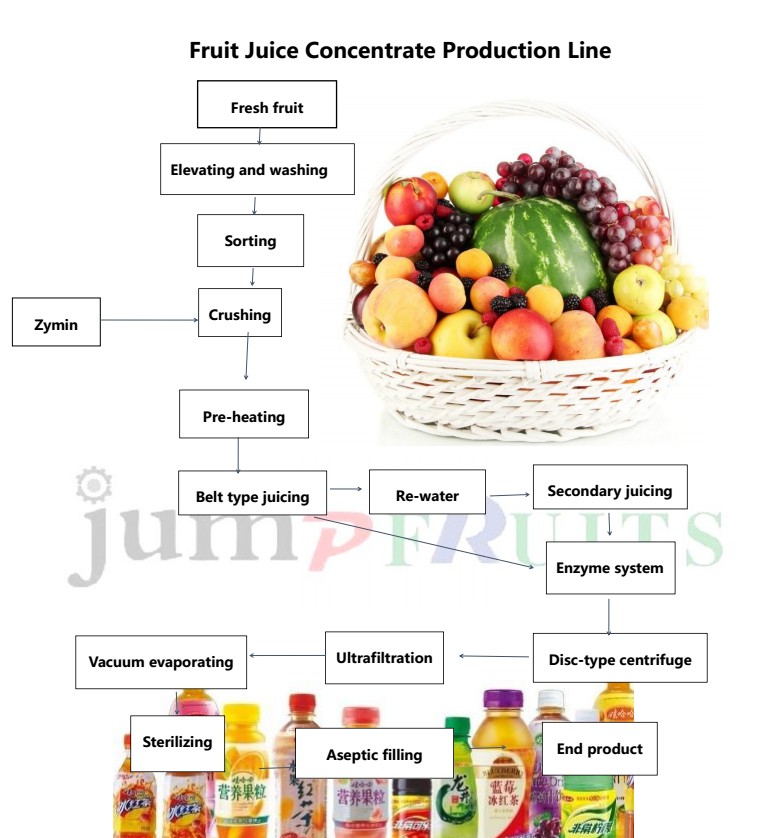

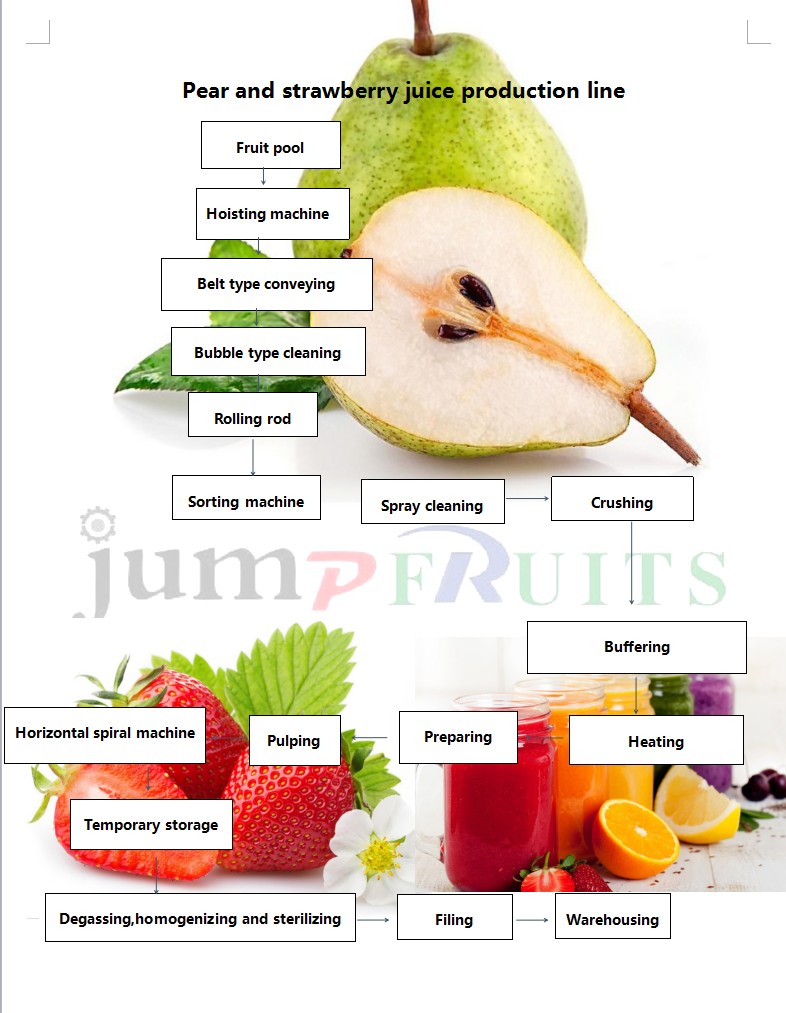

Umugqa wokukhiqiza ijusi yezithelo

Izinzuzo Zethu:

1.Isixazululo se-Turnkey.Asikho isidingo sokukhathazeka uma wazi okuncane mayelana nendlela yokwenza lesi sitshalo ezweni lakini. Asikunikezeli nje kuphela okokusebenza, kodwa futhi sihlinzeka ngezinsizakalo zokuma okukodwa,kusukela ekuklanyweni kwendawo yakho yokugcina impahla (amanzi, ugesi, abasebenzi), ukuqeqeshwa kwezisebenzi, ukufakwa komshini nokulungisa iphutha, insizakalo yempilo yonke ngemva kokuthengisa njll.

Iminyaka engu-2.15 isipiliyoni sokuthekelisa, ukuthutha kalula impahla uye emnyango wakho

I-3.isevisi eyenziwe ngokwezifiso, sizozama konke okusemandleni ethu ukuze sihlangabezane nemfuneko yakho.

4.Isiqinisekiso sekhwalithi: izinyanga eziyi-12.Ngemva kwalokho, onjiniyela nabo bayatholakala ezindlekweni zakho zokuhamba kanye nezindleko zezingxenye ezisele.Sinikeza isevisi yempilo yonke ngemva kokuthengisa.

Izinzuzo eziyinhloko zomugqa wethu wesistimu:

1. Ijubane eliphezulu lokukhiqiza elizuzwe ngesistimu yekhanda esanda kuklanywa (ikhanda elilodwa noma amakhanda angamawele atholakalayo), ukwethembeka okuthuthukisiwe kusuka kumodi yokusebenza elawulwa ngokugcwele ye-PLC yokuxilonga.

2. Ukuguquguquka okukhulu ngokuhlangabezana namazinga ahlukahlukene okupakisha ngemikhiqizo ehlukene.

3 Isebenzisana kahle neshubhu yesibulali magciwane seshubhu, uma ukungasebenzi okuthile ngesigcwalisi, umkhiqizo uzogeleza ubuyele ethangini le-buffer ngaphambi kwesibulala-magciwane se-UHT.

4. Ukusetshenziswa kwesikhwama esingenalutho esivalwe nge-hermetically kuqinisekisa ukuthi isikhwama sizohlala siyinyumba ngaphambi kokuba sigcwaliswe.

5. I-high pressure saturated steam isetshenziselwa ukuvalwa inzalo kokufakwa, i-cap kanye nengxenye eveziwe yesigcwalisi ngaphambi komjikelezo ngamunye wokugcwalisa.AKUKHO KHEMIKALI kudingekile.

6. Ukubekwa uphawu kwe-valve yokugcwalisa ngaphakathi kwendawo yokufakwa kugcina umkhiqizo ungekho ngokuphelele endaweni yokuvala iphakheji.

7. Ukuvalwa kokushisa kwe-hermetic kokufakwa kunikeza ukuvala okubonakalayo kwe-tamper kanye nomgoqo we-oxygen ophakeme.

8. Umklamo jikelele we-aseptic we-filler uvumela ukungaphazanyiswa.Ukusebenza kuyo yonke inkathi katamatisi/yezithelo, ukhulise ukusebenza kahle kwesitshalo sakho

9. I-CIP kanye ne-SIP kuyatholakala kanye neshubhu yesibulali magciwane

Khetha ubakaki bensimbi engagqwali, izinga lokudla kanye nepulasitiki eqinile noma i-stainless steel scraper, i-smoothing blade architecture ukuvimbela ujamu wezithelo;Ukusebenzisa ama-anti-corrosion bearings angenisiwe, uphawu olunamacala amabili;enenjini yokudlulisa eguquguqukayo eqhubekayo, isivinini esishintshashintshayo kanye nezindleko zokusebenza eziphansiIsihloko singena lapha.

I-Stainless steel roller conveyor, ukujikeleza nesixazululo, uhla olugcwele lwesheke, asikho isidingo esiphela.Inkundla yesithelo eyenziwe ngabantu, ubakaki wensimbi ependiwe ye-carbon, insimbi engagqwali ye-antiskid pedal, ucingo lwensimbi engagqwali.

C. Crusher

Ukuhlanganiswa kobuchwepheshe base-Italy, amasethi amaningi esakhiwo se-cross-blade, usayizi we-crusher ungashintshwa ngokuvumelana nekhasimende noma izidingo ezithile zephrojekthi, kuzokwandisa izinga lejusi lejusi lika-2-3% ngokuhlobene nesakhiwo sendabuko, esifanele ukukhiqizwa kuka-anyanisi. isoso, isanqante sauce, pepper sauce , apple sauce nezinye izithelo nemifino isoso kanye nemikhiqizo

D. Umshini wokudonsa ophindwe kabili

Ine-tapered mesh structure futhi igebe elinomthwalo lingalungiswa, ukulawula imvamisa, ukuze ijusi lihlanzeke;Imbobo ye-mesh yangaphakathi isekelwe kukhasimende noma izidingo ezithile zephrojekthi ukuze u-odwe

E. Evaporator

I-Single-effect, i-double-effect, i-triple-effect kanye ne-evaporator enemiphumela eminingi, ezokonga amandla engeziwe;Ngaphansi kwe-vacuum, ukushisa okuqhubekayo komjikelezo wezinga lokushisa eliphansi ukuze kukhuliswe ukuvikeleka kwemisoco entweni kanye neyoqobo.Kukhona uhlelo lokubuyisela umusi kanye nesistimu ye-condensate ephindwe kabili, inganciphisa ukusetshenziswa kwesitimu;

F. Umshini wokuvala inzalo

Ngemva kokuthola ubuchwepheshe obunelungelo lobunikazi obuyisishiyagalolunye, thatha izinzuzo ezigcwele zokushintshisana kokushisa kwempahla ukuze wonge amandla– cishe u-40%

F. Umshini wokugcwalisa

Yamukela ubuchwepheshe be-Italian, inhloko encane kanye nekhanda eliphindwe kabili, ukugcwaliswa okuqhubekayo, ukunciphisa ukubuyisela;Ukusebenzisa umjovo we-steam ukwenza inzalo, ukuqinisekisa ukugcwaliswa kwesimo se-aseptic, impilo yeshalofu yomkhiqizo izoshintsha iminyaka ekamelweni lokushisa;Enqubweni yokugcwalisa, kusetshenziswa imodi yokuphakamisa i-turntable ukugwema ukungcoliswa kwesibili.

Isevisi yangemuva kokuthengisa

1.Ukufakwa kanye nokugunyazwa: Sizothumela onjiniyela abanolwazi nabasebenzi bezobuchwepheshe ukuthi babe nesibopho sokufakwa nokusetshenziswa kwezisetshenziswa kuze kube yilapho okokusebenza sekufanelekile ukuze kuqinisekiswe ukuthi okokusebenza kusesikhathini futhi kuyafakwa ekukhiqizeni;

2.Ukuvakasha okuvamile:Ukuqinisekisa ukusebenza okuzinzile kwesikhathi eside kwemishini, sizobe sisekelwe ezidingweni zamakhasimende, sinikeze okukodwa kuya kwezintathu ngonyaka ukuze size ekusekelweni kwezobuchwepheshe nezinye izinsizakalo ezididiyelwe;

3.Umbiko wokuhlola onemininingwane: Kungakhathaliseki ukuthi isevisi evamile yokuhlola, noma isondlo saminyaka yonke, onjiniyela bethu bazohlinzeka ngombiko wokuhlola onemininingwane yekhasimende kanye nenqolobane yereferensi yenkampani, ukuze kufundwe ukusebenza kwesisetshenziswa nganoma yisiphi isikhathi;

I-4.I-inventory yezingxenye ezigcwele ngokugcwele: Ukuze unciphise izindleko zezingxenye ku-inventory yakho, unikeze isevisi engcono futhi esheshayo, silungiselele iqoqo eliphelele lezingxenye zemishini, ukuhlangabezana namakhasimende isikhathi esingenzeka sokufuna noma isidingo;

5.Ukuqeqeshwa kochwepheshe kanye nobuchwepheshe:Ukuze kuqinisekiswe ukusebenza kwezisebenzi zezobuchwepheshe zekhasimende ukujwayela okokusebenza, ukubamba kahle ukusebenza kwemishini nezinqubo zokuyilungisa, ngaphezu kokufaka ukuqeqeshwa kobuchwepheshe esizeni.Ngaphandle kwalokho, ungakwazi futhi ukubamba zonke izinhlobo zochwepheshe kuma-workshops asefekthri, ukukusiza ukubamba ubuchwepheshe obushesha futhi obuphelele;

6.Izinsizakalo zeSoftware kanye nezokubonisana: Ukuze uvumele abasebenzi bakho bezobuchwepheshe ukuba babe nokuqonda okwengeziwe kokwelulekwa okuhlobene nemishini, ngizohlela ukuthumela amathuluzi athunyelwa njalo kumagazini wezeluleko kanye nolwazi lwakamuva. Asikho isidingo sokukhathazeka uma wazi okuncane ngakho. ungasifeza kanjani lesi sitshalo ezweni lakini.Asikunikezeli nje kuphela izinto ezisetshenziswayo, kodwa futhi sihlinzeka ngensizakalo yendawo eyodwa, kusukela ekuklameni kwakho kweshede (amanzi, ugesi, umusi) , ukuqeqeshwa kwesisebenzi, ukufakwa kwemishini nokulungisa iphutha, impilo yonke isevisi yangemuva kokuthengisa njll.